There are entire books, thorough training and certification processes all devoted to lean supply chain practices. But within any manufacturing environment, there are a few relatively simple steps that will help any enterprise lean their supply chain. In this white paper, we will touch on these simple measures—measures that any company can take.

Lean in a supply chain context is about a holistic view of procurement, manufacturing distribution and sales order processing. This means that some level of enterprise technology is necessary to view the organization in an integrated context instead of as functional islands. However, before technology can facilitate the lean supply chain, manufacturing executives need to start thinking in lean supply chain terms. We will be reviewing those terms and sharing the key concepts that are the foundation for the lean effort.

In short, we will discuss:

- Four tips to help you bring lean supply chain improvements to your manufacturing operation.

- Six technology tools that help automate these lean supply chain practices.

We will use a few practical examples along the way to illustrate these concepts, but our main goal will be to define the specific things manufacturing executives can do to lean their supply chain.

Tip one: resolve conflict Between Manufacturing efficiency and customer service

One company that I have been involved with from a lean supply chain perspective is a manufacturer of paints and coatings. After implementing their new enterprise application (ERP), they wanted to use the new-found visibility of their operations to implement a lean supply chain program. They found that before you can lean an organization, you have to have a good idea of what your current operations and processes really are. Then, once you know what you are doing, you can decide on process changes and then measure to what extent those changes have reduced nonvalue-added work.

What became immediately apparent is that like most manufacturers, this company faced the same conflict between the need to be efficient in production and the need to be responsive to customers. The manufacturing department tended to schedule for maximum efficiency by producing very large batches. This enabled efficient purchase or raw materials, maximum return on machine set-up time, manufacturing personnel and other costs. Large batches are simply a good way to minimize the cost per produced unit. Low cost-per-unit is attractive, but it is in conflict with the goals of the sales organization. While manufacturing is rewarded for efficiency, the sales department is rewarded for serving the customer, which in turn leads to increased revenue and commissions. If manufacturing commits production capacity to large runs that are not immediately tied to customer demand, it might be difficult to meet the needs of customers as those needs change and fluctuate during the year. An item that is requested might not be in stock and may not be scheduled for production at a time when immediate capacity is committed due to the high-volume production schedule. Moreover, these large production runs mean that large amounts of capital are tied up in finished product inventory long before any revenue can be realized.

In the case of food and beverage and some other process industries, these large production runs can also result in spoilage as the effective life of raw materials and finished goods is spent sitting on the shelf.

The paint manufacturer did the obvious thing … decrease their batch sizes. Going forward, manufacturing would not be making unilateral decisions about batch sizes and production schedules, circumventing their natural tendency to focus on manufacturing efficiency. Instead, they would now be obliged to produce only enough to cover a certain period of time based on the sales projection. That means that every product will now be produced more frequently and in smaller batches. To encourage this behavior other metrics and KPI’s can be introduced that are more holistic and based on customer service levels and inventory turns, rather than just production output.

There are any number of formal disciplines designed to tie production in with sales forecasts. Sales and Operations Planning is one such method. By tying manufacturing schedules on sales projections that typically look a short distance into the future, you will be manufacturing what customers are actually asking for, improving customer service and allowing greater responsiveness. Your inventory levels will decrease in proportion to your inventory turns. The higher the speed through the supply chain, the higher the inventory turns and the less capital tied up in inventory at any given time. At the same time, the faster the raw materials move through the supply chain, the less obsolescence you have and less expired materials you have.

Tip two: extend systems to suppliers

Once the basic problem of aligning manufacturing schedules with demand is taken care of, the greatest bottleneck to improved supply chain efficiency is often the disconnect between internal scheduling processes and those of external suppliers. Companies who are vendors to major OEMs know that large manufacturers are working to eliminate this bottleneck, and are often working with suppliers on a proactive basis to help them become more responsive.

Technology can play a vital role in eliminating this constraint. In the case of our paint and coatings manufacturer, one of their main bottlenecks was packaging. They outsourced printing on the cans their product was shipped in, which meant that the supplier cannot finalize their own can production schedule until they know the exact product numbers that will be filled. Their packaging actually took longer to produce than the manufacture of the product itself. Even though the cost of the packaging is low in comparison to the actual product to be filled, the scheduling of the packaging supply is one of the most critical and difficult parts of the production planning.

Technology can play a vital role in eliminating this constraint. In the case of our paint and coatings manufacturer, one of their main bottlenecks was packaging. They outsourced printing on the cans their product was shipped in, which meant that the supplier cannot finalize their own can production schedule until they know the exact product numbers that will be filled. Their packaging actually took longer to produce than the manufacture of the product itself. Even though the cost of the packaging is low in comparison to the actual product to be filled, the scheduling of the packaging supply is one of the most critical and difficult parts of the production planning.

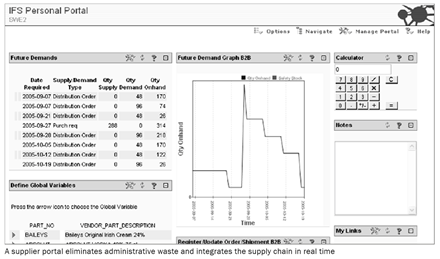

The solution was to set up supplier portal so that the packaging vendor and other suppliers could look into the production plan and prepare their own schedule accordingly. This eliminates a lot of the manual and administrative work involved with interfacing with a supply chain partner in real time, removing all manual intervention and administrative delays. Portals of this nature can also provide a longer view of anticipated production so that vendors can manage their own inventories and plan their own capacity according to anticipated demand.

Tip three: run parallel MRP processes

To clarify, this tip does not have as much to do with running parallel systems for manufacturing resources planning (MRP) as much as it is about delaying the commitment to manufacture to a point where demand is visible, known or certain. Even as companies try to focus on the disciplines normally associated with the idea of a lean supply chain, this is another fundamental paradigm shift that must take place within their organization, and it is often overlooked.

For instance, many companies operate with one single manufacturing resources planning (MRP) process. Consider that company that manufactures in a make-to stock (MTS) mode, whose executives feel that this single MTS enterprise system is adequate for their needs. This attitude is fine if a manufacturer has a stable, predictable demand for all of its products. But in reality, few manufacturers have the luxury of flat demand. More often the rule of Pareto is applicable. This rule suggests that 20 percent of products have a stable demand, and you can manufacture them efficiently in large quantities. But the other 80 percent of a manufacturers’ part numbers are ordered less frequently, and therefore need to be treated differently in the company’s processes, systems and scheduling. This is why virtually any MTS manufacturer should run in multiple manufacturing modes. Most MTS manufacturers would benefit from a parallel make-to-order (MTO) system. This will avoid the stockpiling of a large number of items that are more effectively handled in MTO mode, freeing up both capital and production capacity for other products, all without sacrificing responsiveness or customer service. By continuously analyzing demand patterns and inventory turns, the point of postponement can be changed over time to achieve the optimal balance between efficiency and responsiveness.

A modern, agile enterprise application (ERP) will include all of the necessary tools to handle these multiple modes. Apart from ensuring that they have the proper enabling technology, manufacturers will need to carefully analyze the demand patterns for their finished goods and divide them into MTS and MTO.

Tip four: Master the demand forecasting process

Too many companies fail to give demand forecasting the attention it deserves, and this is often the undoing of even the most aggressive lean supply chain project. If you think of a demand forecast, the more accurate it is, the better position you are to supply to the market what the market needs. Conversely, basing a lean supply chain effort on an inaccurate demand forecast is like building a house on a foundation of sand.

Too many companies fail to give demand forecasting the attention it deserves, and this is often the undoing of even the most aggressive lean supply chain project. If you think of a demand forecast, the more accurate it is, the better position you are to supply to the market what the market needs. Conversely, basing a lean supply chain effort on an inaccurate demand forecast is like building a house on a foundation of sand.

If you can increase the demand forecast accuracy, you can decrease your inventory and increase your level of customer service at the same time. Unfortunately, most companies divide responsibility for the demand forecast among multiple departments.

Sometimes, the process is owned by the sales department, and they tend to be too optimistic because optimism is in their nature and they want to avoid disappointing a customer by being out stock. At the end of the day, no one is specifically responsible for forecast accuracy, perhaps in part because the company lacks the proper tools to develop an accurate forecast. It is not surprising that, as a result, this crucial role tends to fall between chairs in many enterprises. It is imperative that a manufacturing enterprise assign demand forecasting to an independent party within the company that has more of a holistic point of view than would sales, manufacturing or any other specific department.

Technology tools to look for

There is no technology or enterprise application (ERP) that will, all by itself, deliver lean supply chain benefits. However, as you embark on your lean journey, you will be much more successful if your enterprise software supports and streamlines your lean efforts instead of preventing barriers to the adoption of lean supply chain practices. Here are five things to look for in enterprise technology to help you make sure that your new enterprise environment is helping and not hurting.

That means that there are some specific things you will want to look for in an enterprise application (ERP). It should almost go without saying that an application should be well-integrated company-wide and provides the visibility necessary to facilitate lean processes. Remember—you cannot improve what cannot measure, so visibility into processes company-wide is necessary for lean supply chain improvements. There are other, less obvious things to look for as well, including:

An integrated solution for quality management that will support your effort to do things right the first time. Without a viable system for getting the appropriate quality out of manufacturing and supply chain processes, it is entirely possible that apparent efficiencies gained in one part of the process will be wiped out by the added effort involved in correcting errors at another part of the process. You need a system that will report and allow you to record quality results and analyze performance on every lot or batch you manufacture through statistical process control. You will then be in a position to see how your process is aligned with your ideal values and then improve the process to reduce the quality failures.

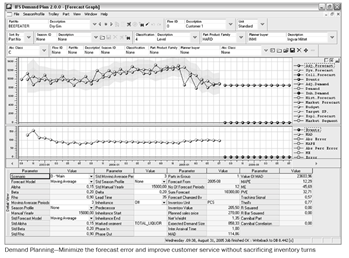

The better the demand forecasting tool in your enterprise application (ERP), the leaner your supply chain will be. The better you know what the customers will ask for, the leaner your supply chain will be. Make sure that demand planning functionality allows multiple users to simultaneously review and give input on demand plans, thereby shortening review cycles and increasing accuracy. It is also import that the demand forecasting tool allows you to export forecasts to various common office applications and emailed to key people throughout the enterprise. In order to increase accuracy, you must be able to easily monitor and take action based on the forecast error, so look for robust error management functionality, including Mean Error, Mean Absolute Error, Mean Absolute Percentage Error, Theil’s U-statistic, and others.

Regardless of your manufacturing mode, make sure that an enterprise application (ERP) supports multiple modes including MTO, engineer to order (ETO), configure to order (CTO) and others. Even straightforward MTS manufacturers need to account for the different levels of demand for various products and part numbers. This will allow you to be efficient on products that make sense to manufacture in large quantities and responsive on products that are best handled as special orders.

An enterprise application (ERP) ought to offer tools that allow production to become pull-based, facilitating processes like Kanban. Strong Kanban functionality will allow companies to pull products through their supply chain, thus leaning the supply chain, minimize work in process, maximize responsiveness and avoid stock piling of finished goods.

Regardless of how many sites you manufacture at, your enterprise application should provide for operations at multiple sites. Because as you begin to think in terms of your supply chain the encompassed vendors, distributors, and customers, plus distribution centers and warehouses, you really are by default operating in a multi-site environment. The better you can integrate and plan for cohesive operations between these different sites, the more responsive you can come as the information flows seamlessly through these nodes, hubs, customers and suppliers—regardless of whether these sites are under your direct control or not. Begin to see multi-site functionality for what it is … a tool for collaboration up and down the supply chain.

Master data management is key, particularly for companies that have recently experienced merger or acquisition activity. Master data management will bring efficiencies to companies that, in different parts of the company, have multiple part numbers for the same item. It is hard to create enterprise wide visibility and integration through the supply chain when you have duplicate data and records for the same part. By extension, it is important, even if your corporate footprint is entirely contained within a single company, to ensure that an enterprise environment allow for multi-currency and multiple language support. Without this, any extension of the application to a customer or vendor overseas will result in duplicate data, quickly undoing your lean supply chain improvements. The bottom line is that both with regard tin internal naming conventions and external communications, you need to have a common, universal, language in for customer numbers, item codes, etc., in order to integrate the business and share your plans and bring lean efficiencies to your supply chain.

Conclusion

Some people might think of lean supply chain technology as having to do entirely with purchasing, distribution, global sourcing and other activities that relate directly with supply chain management. But we know that within a manufacturing enterprise, everything impacts everything else, and in order to make real progress, we need to see things holistically across the enterprise. Lean supply chain improvements require a commitment for the top of the organization to configure the company for that correct blend of efficiency and responsiveness. It requires the creativity to open the manufacturer’s internal processes to vendors and customers. And it requires a commitment to the disciplines of multiple-mode manufacturing and demand planning.

But the reward is great for those manufacturers that do embark on this lean path, and those rewards should show up clearly on the bottom line. Lower investment in inventory, greater customer satisfaction, less work involved in managing suppliers are the benefits you can realistically expect to realize when you use the right enterprise application (ERP) to bring lean to your supply chain.