Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) applications both touch the industrial maintenance space. One might say that the relationship between the two is rather like that between a square and a rectangle … every EAM application can be used as a CMMS, but not every CMMS can be used as, or has the broad functionality of, an EAM application. More specifically, CMMS is essentially about managing maintenance work necessary to sustain an asset, whereas EAM has more to do with managing the asset over its lifecycle to minimize cost and risk while maximizing return. But how exactly do CMMS applications and EAM applications drive value? How do you know if your company ought to implement one versus the other?

CMMS

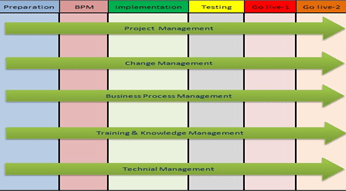

CMMS may be thought of as a communications tool that allows us to communicate about maintenance activities in the same way, using the same words, every time. It provides documentation of that communication through work orders so essential maintenance activities do not get forgotten. CMMS systems are in fact designed to do a lot of other things for us; collecting material costs and labor costs and serving as a repository for all of our maintenance information.

There are definite problems that a CMMS, as that communication too, can solve. Without a work order process that is used for every job, we have no documentation of what our most problematic pieces of equipment are. But once a company implements a CMMS system and takes on the attitude that “the work order is king, and nothing happens without a work order,” that problem is solved. Complete visibility into what work is being performed on which pieces of equipment can help us achieve things like Preventive Maintenance (PM) and Predictive Maintenance (PDM), and can even help with the repair or replace decisions as problems become more recurrent and expensive to solve. But technicians can be resistant to the idea of recording any and all work in the CMMS. Why? Often, it is because they think the CMMS is being used to monitor their activities and ensure they are doing their jobs. A better way to think about the CMMS and work orders is that it is a way to prove maintenance value to the organization. In effect, anytime maintenance is doing work outside of the work order system, regardless of whether you are using CMMS or EAM, you are doing work for free. Every maintenance organization feels they are understaffed, but few are able to accurately document what their true work load is. If they could, it would help them identify the appropriate staffing level. Documenting and managing work is one way to look at CMMS. Documenting and managing equipment is another. Consider the problem faced by a company with a three shift operation, with every shift spending 20 minutes doing a quick repair on the same piece of equipment. If that quick 20 minute job is not being captured by a work order within the CMMS, you have is an invisible problem because communication from shift to shift isn’t taking place. What that means is that in a manufacturing environment, the line can be down 20 minutes every shift every day for years, which really amounts to 60 minutes per day, up to 365 days per year. That is a tremendous waste. CMMS can help identify and ultimately eliminate that waste, provided it is documented. Lost productivity is one problem a CMMS can solve. Another is undocumented use of maintenance inventory, including parts and consumables. Many medium to small organizations don’t man their store rooms, and so often, someone will grab a part with the intention of documenting what they took later. But many times, they fail to or forget to document what they used and where they used it. The inventory system thinks those items are still on the shelf, causing shortages (stock-outs) that can in turn lead to down time when a necessary part is not available. Through the reinforcement of processes, procedures, and documentation one can create a culture of discipline across a maintenance organization can be established. If the CMMS work order system in place enables standardized, repeatable, and sometimes predictable processes that could prevent work from being missed or forgotten, documents problems so they can be fixed and ensures the usage of labor and parts or materials utilized are recorded.

Many CMMS systems are in fact capable of facilitating much more than work orders and maintenance inventory management. But even though a CMMS offers more advanced functionality, it often goes unused since it is considered a “maintenance program”.

Many CMMS systems are in fact capable of facilitating much more than work orders and maintenance inventory management. But even though a CMMS offers more advanced functionality, it often goes unused since it is considered a “maintenance program”.

The difference Some may say that there is not a whole lot of difference between a CMMS and EAM. EAM certainly offers a broader spectrum of functionality. And the delineation between the two may be drawn at purchasing functionality. Most CMMS applications have purchasing functionality, but it is often not used. A company using a CMMS will often integrate it point-to-point with a purchasing system, or the two functions may be handled in entirely separate applications. On the other hand, EAM applications have extensive purchasing, planning and financial functionality that the application is to a certain extent built around. Many CMMS packages will also start to look kind of similar to an EAM application because they allow you to manage projects. Some CMMS applications even have a project module that integrates and uses work orders and builds parent-child work orders, all aimed at shut downs and other maintenance events. It could be that this functionality is not strong enough or it is just not something those running the CMMS are aware of. Because it seems the natural tendency is to use Microsoft Project, or Primavera, which means we induce problems by doing things outside of the work order system. Again CMMS is seen as having to do with work orders and maintenance, and a company choosing CMMS over EAM may not be looking for that additional functionality. The choice between CMMS and EAM can also be influenced by the size of the maintenance organization and where, within the company, the software decision is made. When a software project is driven by the maintenance department, they are typically selecting CMMS, because they are not normally directly involved in selecting more enterprise-level systems or applications. Furthermore, a small to medium sized maintenance organization with 75 or fewer maintenance technicians in the organization will typically migrate to a CMMS. Once you have more than 75 maintenance technicians, they tend to migrate to an EAM application. As a company has more maintenance technicians, human resources and other roles to integrate with the maintenance work force probably becomes more desirable. Moreover, a company whose entire operation centers to a large degree around maintaining, sustaining and operating assets will want technicians and even contractors working with them to be managed directly in and from their enterprise systems. To most organizations, that level of sophistication in a system is exotic. And what happens, unfortunately, is that many organizations implementing CMMS or EAM may be advised to look at a full cradle to grave asset lifecycle management approach. But they balk, insisting “We just want to concentrate on getting the assets in there and making sure our PMs are getting done.” So they really pass up an opportunity to select an application capable of broader asset management duties or even, if a more powerful application is selected, lay the requisite ground work during implementation to use the functionality. Most selection and implementation teams are under pressure to quickly get assets into the system and keep the PM program rolling. Once they accomplish that initial implementation goal, they never make time to go back in and do more to or with the system. So whoever is helping them implement must drive them to try and embrace all of the capabilities of that system. Typically CMMS applications may be used at only 50 percent or less of the total system capabilities. EAM is very much the same way. I think from the EAM side, it is considered more cost driven because there is a lot more asset information, there is a lot more work and people may say to themselves, “I don’t have the time, the money or the resources to do this fully. I will do it over time.” But they never get back in there and do it over time.

EAM

In contrast to CMMS, EAM is an enterprise-wide application that can function just like an enterprise resource planning (ERP) application for an asset-intensive business – from the general ledger through to purchasing and projects and engineering and individual work orders. Or, as is the case of IFS Applications, it can be implemented to include as much enterprise functionality as is required and integrated through application programming interfaces (APIs) with other enterprise systems.

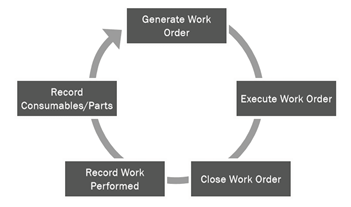

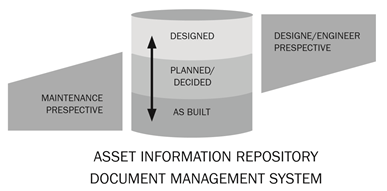

While CMMS is designed, in its purest form, to manage the maintenance work so as to improve asset reliability, EAM is designed to allow the executive level to maximize the productive value of the asset, which of course means they need full visibility into maintenance costs. At the same time, they need visibility into the cost to initially construct the asset, the cost of replacement or lifecycle extensions, the cost of maintenance contractors and of course the human costs associated with salaries, benefits, and more. They also need to evaluate risks presented by the asset, so asset integrity management and risk management is of critical importance particularly for companies where asset failure can result not only in lost productivity but safety breaches or environmental impacts. At a base level, EAM must deliver the core requirements not just of maintenance management, but asset management. Those requirements are spelled out in ISO 55000, ISO 55001 and ISO 55002. ISO 55000 includes an overview of asset management. ISO 55001 is a requirements specification for an integrated asset management system, and ISO 5502 offers guidance for implementation. While ISO 55000 does not specifically address software, it does require that all asset data, across the lifecycle of the asset and across organizational boundaries, be contained in the same database and therefore, the same system. What does that mean? It means EAM must support the planning and engineering stage of the asset, including plant design. It must encompass the construction of the asset, so powerful project, document and contract management functionality is required. And it must support operation of the asset and even eventual decommissioning and replacement. This is a demanding requirement that CMMS alone cannot likely meet, and frankly, neither can most EAM applications that may not address the entire asset lifecycle. And whether or not a company considers adopting the ISO standard, if they are committed to complete visibility and control over their assets, they still need that full lifecycle support. Only a single system like EAM can deliver an accurate and consistent view of all asset information—one version of the truth—insuring policies, plans, and actions are based on an accurate understanding of the history and current status of your asset infrastructure. In order to accomplish this, an EAM software product must actually address all phases of the asset lifecycle, and not many do. It must also provide portals or other methods for outside parties like engineering firms and maintenance contractors to use the system so that everyone touching that asset data is interacting with a single database in real time. And by everyone, we mean people inside and outside the company. An EAM application must offer the ability to open portals to suppliers like engineering firms and maintenance contractors. As you plan maintenance work for the weeks ahead, if your contractors have visibility of your plans through your EAM system, they can be informed of the upcoming work, schedule their people and ensure that they have the right tools and materials available. If they are seeing that rolling schedule, they can be more responsive to your needs. This also reduces the amount of time necessary to manage those outside contractors by phone and email. Moreover, if the contractor can report their work activities directly into your system, you are getting real-time updates of work completed. That eliminates the delay that results when the contractor enters the data in their own system, and the data flows through reporting mechanisms within that contractor environment and back to the manufacturing maintenance team, which then has to enter that record of work back into the EAM, enterprises resources planning (ERP) or computerized maintenance management (CMMS) software. That repeated entry is wasteful and increases the likelihood of mistakes. Real-time data can also allow for tighter coordination between the contractor and internal maintenance staff or with other contractors working on that asset. Moreover, that real time data could allow for more efficient use of the asset, as in the resumption of a production schedule immediately after a contractor finishes work.

Advanced project management Project management is of interest not just to the maintenance or plant manager who may want to manage a plant shutdown, but the CEO, CFO, board or other stakeholders who may want to manage the lifecycle of an asset as one long project— a project that might last for as long as 20 or more years. The asset lifecycle is really just a project that starts with engineering and construction processes. The project then comes to include the cost to maintain, operate and refit, and culminates with a well-informed decision to decommission and replace the asset. In the absence of fully functional, flexible and integrated EAM and ALM systems, managing the lifecycle of the asset from cradle to grave is a challenge. What this means to a software selection process is that the ability of an EAM package to support plant design and engineering ought to be a major factor. Even in the vast majority of instances when an outside engineering group is responsible for design, their activities ought to be encompassed by the EAM platform to be used during the asset lifecycle so that design data flows naturally into the maintenance and operations systems that will sustain the asset during its productive life. Tight integration between ALM, project management and core EAM functionality is also necessary. Consider for a moment the situation faced by the chief executive and maintenance director at a coal-fired power plant that has one stop per year for major overhauls. There is a pressing need to meet the project timeline because each day of downtime is worth millions of dollars, and there is a significant degree of project complexity as outside contractors are hired, equipment is rented and perhaps additional maintenance shifts are added. Robust project management functionality that is integrated on a very granular level with a powerful EAM application can help manage the resources necessary to complete the required tasks in the time allotted. While the ability to manage to meet the deadline is one strong argument for integrated project and EAM functionality, even greater benefit can be realized of project and EAM functionality are tied into an overarching asset lifecycle management (ALM) system and the general ledger. The ability to look at a plant shutdown from an ALM and financial perspective can help determine if it makes sense to bring in additional outside resources in order to shorten the amount of down-time. To what extent will the outside cost of hiring contractors and equipment increase total return on the asset in the intermediate to longer term? Many asset-intensive companies do not have in place the proper tools to efficiently optimize the activities associated with a plant shut down, and certainly do not have the right tools to proactively reduce planned downtime. But this effort to track the cost of operating and maintaining the asset is dependent on effective cost tracking on thousands of smaller projects. On this micro level, integrated project, finance and EAM functionality is critical. When working in a properly-integrated enterprise application, it is much easier to structure a maintenance project to collect all of the cost, including procurement and work orders that are used to collect technicians’ time. Integrated functionality will also allow analysis of project cost by different breakdown structures, and each activity a can be assigned a different funding line. So it becomes that the difference between EAM and CMMS has to do not only with the breadth of functionality, but the degree to which that broader functionality is designed to work together to deliver a unified asset management platform.

The desired future state While CMMS is designed to meet immediate maintenance management needs, EAM is designed to manage the future state of the asset, providing visibility into the past and driving predictability into the future. It is this ability to look into the future state of the asset that is affecting everything from lifecycle extensions to plant location decisions. In Brazil, we are seeing tremendous growth in the paper pulp industry. Why is this? Because executives can see that the productivity of an asset in that location is much higher and lower cost than one in a more northern clime. In Brazil, there are entire valleys that are completely empty of trees after a thorough harvesting. But just seven years later, that valley is home to a full grown forest—a forest growing in flat fields so when they come in with your harvesters, there are no natural barriers. That seven-year harvesting cycle versus the 150-year harvesting cycle common to a more northern clime has real asset lifecycle implications. The future state a company implementing EAM can aspire to can be a lot simpler than this though. They may aspire to lower cost by truly managing an extensive maintenance inventory in an intelligent way. Inventory management requires a unique master ID for part Identification in the asset intensive industry. This ID must be standardized, and IFS has been on the forefront of identifying a universal standard for parts, and within IFS Applications certainly standardizes part numbers across all facilities a company may operate. Why is this important from an EAM standpoint? Because it allows management to reduce the ongoing investment required to manage the asset. If you look at a multisite, asset-intensive industry, there might be 100,000 different parts or objects in that asset environment. You might have 50,000 different spare parts in your inventory and all of these are named in a very localized way. That is because the part naming convention was likely developed site by site over the decades, and the problem may be a lot worse if the company has grown by acquisition. Therefore, it is impossible to know that a motor in company A, called Alpha, is the same motor as company B is storing under the name Beta. With part enterprise part standardization, you can suddenly you can start to treat stock levels at different sites with a higher degree of transparency because you suddenly understand that this motor is stored in all of the five sites in your group. And the expected level that you need to have on the shelf is maybe 0.2 of this motor, which means you need to store at least one. But if you suddenly treat these five sites as one common unit with different inventory locations for this motor, you would in theory be able to store just one motor to service all five sites and you would still be able to ensure coverage.

The desired future state While CMMS is designed to meet immediate maintenance management needs, EAM is designed to manage the future state of the asset, providing visibility into the past and driving predictability into the future. It is this ability to look into the future state of the asset that is affecting everything from lifecycle extensions to plant location decisions. In Brazil, we are seeing tremendous growth in the paper pulp industry. Why is this? Because executives can see that the productivity of an asset in that location is much higher and lower cost than one in a more northern clime. In Brazil, there are entire valleys that are completely empty of trees after a thorough harvesting. But just seven years later, that valley is home to a full grown forest—a forest growing in flat fields so when they come in with your harvesters, there are no natural barriers. That seven-year harvesting cycle versus the 150-year harvesting cycle common to a more northern clime has real asset lifecycle implications. The future state a company implementing EAM can aspire to can be a lot simpler than this though. They may aspire to lower cost by truly managing an extensive maintenance inventory in an intelligent way. Inventory management requires a unique master ID for part Identification in the asset intensive industry. This ID must be standardized, and IFS has been on the forefront of identifying a universal standard for parts, and within IFS Applications certainly standardizes part numbers across all facilities a company may operate. Why is this important from an EAM standpoint? Because it allows management to reduce the ongoing investment required to manage the asset. If you look at a multisite, asset-intensive industry, there might be 100,000 different parts or objects in that asset environment. You might have 50,000 different spare parts in your inventory and all of these are named in a very localized way. That is because the part naming convention was likely developed site by site over the decades, and the problem may be a lot worse if the company has grown by acquisition. Therefore, it is impossible to know that a motor in company A, called Alpha, is the same motor as company B is storing under the name Beta. With part enterprise part standardization, you can suddenly you can start to treat stock levels at different sites with a higher degree of transparency because you suddenly understand that this motor is stored in all of the five sites in your group. And the expected level that you need to have on the shelf is maybe 0.2 of this motor, which means you need to store at least one. But if you suddenly treat these five sites as one common unit with different inventory locations for this motor, you would in theory be able to store just one motor to service all five sites and you would still be able to ensure coverage.

Mobility

The futurist William Gibson was right … the future is here, but it is just not evenly distributed. Some companies have achieved part standardization. The technology is there, but the will to implement is not yet universal. This is also the case with enterprise mobility, which a modern enterprise asset management application can also facilitate. Mobility comes through EAM in different ways to different people in the enterprise. For the executive, an EAM system will be able to notify them on their smartphone or other mobile device when urgent documents need to be approved. Those working in an office or managerial environment will have full access to their EAM suite on touchscreen devices like tablets. And technicians will be able to use consumer-grade smartphones and other mobile devices to access and complete work orders. The technology is here, and forward-looking companies are taking advantage of it.

Conclusion

EAM and CMMS are related, with CMMS being used to address immediate maintenance management needs and EAM extending across other enterprise functions. Companies operating large, expensive or mission critical assets with many maintenance technicians will do well by selecting and implementing EAM. A company with more immediate needs may want to implement CMMS, but perhaps opt for an application that can grow with them, expending in a modular and flexible way to deliver full-blown EAM.