In industrial maintenance, utilities and other asset-intensive industries, plant managers are telling maintenance managers they want them to implement the RCM (reliability-centered maintenance) processes they keep reading about in trade magazines. But many don’t really understand what RCM means or what level of organizational commitment and development are necessary to achieve it.

As a business consultant with IFS, the global enterprise software company, I get asked by customers all the time about implementing RCM. I make sure to tell them that while enterprise asset management (EAM) software can support the goal eventually implementing RCM philosophies and methodologies.

In order to explain how to gauge where a company’s maintenance program stands and where its goals need to ultimately lie, we need a term that is all encompassing of the total maintenance-management-process approach and ultimate goal. I call this Quintessential Asset Management (QAM). The word quintessential comes from ancient physics as the fifth element that holds the other four elements of earth, wind, air and fire together. Think of maintenance as the fifth element that brings and keeps a profitable asset-driven business together. In modern English, quintessential has come to mean the model that a concept strives to become.

In embarking on your QAM journey, the first questions to ask yourself are where is your company’s maintenance program today and where do you want to take it. An enterprise needs to establish a valid benchmark of where it stands, set realistic goals and then evaluate its progress honestly and openly at predetermined intervals.

In this white paper, we’ll outline the five levels of asset-management development a company usually passes through leading to more advanced processes such as RCM to eventually achieve QAM. In describing these levels of development, it makes sense to use terminology we can already relate to, so we will compare it to a familiar analog—human development.

Level one—Disruptive/reactive (infancy)

The first stage of development in asset management can be compared to infancy. At this stage, a company’s maintenance program is starting from ground zero.

There is literally no maintenance department. Things are breaking down; operations personnel are screaming and every breakdown or failure results in production being thrown into crisis mode.

Anyone who has had an infant in their home can relate to being in a disruptive/ reactive mode day and night. Substantial resources and attention are devoted to responding to the child’s every need, and although first-time parenting usually comes without training, machine repair should be left to trained professionals. Unqualified personnel often try to repair or rig the machinery to get a run completed. Companies at this stage of development also depend heavily on contractors, which although safer are expensive and usually not a replacement for on-site personnel. In-house technicians who see the equipment every day get a feel for why disruptions occur and can help prevent the problems from recurring.

I have worked in various support and managerial capacities for companies that did not have a maintenance department. Knowing my technical background, many times, I’d be sitting at my desk when someone would run in and ask me if I would get out on the floor and see if I might be able to help repair a machine and get production back up least we miss an important order. If this happens in your company, you definitely need to consider the benefits of having onsite maintenance personnel and the genesis of a structured maintenance program.

Level two—folders and spreadsheets (Childhood)

As an infant develops into and through childhood, they become self-sustaining. A company whose maintenance function is entering this stage of development will begin to hire their first maintenance employees. They might hire one or two technicians, and perhaps even have one of them spend time in an administrative function, creating a maintenance program that is usually calendar-based in a personal information manager (PIM) like Microsoft Outlook. So at this juncture, the technician(s) begin plotting calendar-driven maintenance activities based on equipment manufacturer’s recommendations. On a daily or weekly basis, they print off a checklist route from a spreadsheet. The work is divided up among the available technicians and saved in folders along with manuals, receipts for more significant parts or materials and notes for future reference.

As an infant develops into and through childhood, they become self-sustaining. A company whose maintenance function is entering this stage of development will begin to hire their first maintenance employees. They might hire one or two technicians, and perhaps even have one of them spend time in an administrative function, creating a maintenance program that is usually calendar-based in a personal information manager (PIM) like Microsoft Outlook. So at this juncture, the technician(s) begin plotting calendar-driven maintenance activities based on equipment manufacturer’s recommendations. On a daily or weekly basis, they print off a checklist route from a spreadsheet. The work is divided up among the available technicians and saved in folders along with manuals, receipts for more significant parts or materials and notes for future reference.

Many companies only move to this level to appease some quality standard for their industry such as QS or ISO. Some companies stay at this level indefinitely, perhaps due to a prevailing notion that if a technician isn’t turning tools on a broken machine, he’s wasting time. More proactive planning and management are not seen as value added items. These are counter-productive attitudes and this is where it becomes advantageous to consider graduating the maintenance program to a more organized approach through implementation of a Computerized Maintenance Management System (CMMS) or EAM software.

Level three—Basic CMMs (Adolescence)

A human being at the adolescent stage of development has a lot of energy and ideas that need structure, documentation, and direction in order for them to develop into a productive, efficient adult. Wouldn’t it be great to have a tool to log a person’s accomplishments and mistakes in order to more effectively grow up? One of the most crucial steps in a company’s maintenance evolution is realizing the value of tracking asset history and having a more organized method for referencing previous causalities and issues other than a technician’s memory. (This also helps preserve hard earned knowledge when experience technicians retire or move on.) Similarly, a maintenance department reaching this level of development will want to take on more accountability for the contribution they are making to the company’s success, and will want to implement systems to help them achieve these ambitions.

A human being at the adolescent stage of development has a lot of energy and ideas that need structure, documentation, and direction in order for them to develop into a productive, efficient adult. Wouldn’t it be great to have a tool to log a person’s accomplishments and mistakes in order to more effectively grow up? One of the most crucial steps in a company’s maintenance evolution is realizing the value of tracking asset history and having a more organized method for referencing previous causalities and issues other than a technician’s memory. (This also helps preserve hard earned knowledge when experience technicians retire or move on.) Similarly, a maintenance department reaching this level of development will want to take on more accountability for the contribution they are making to the company’s success, and will want to implement systems to help them achieve these ambitions.

It is at this point in a maintenance department’s development that a CMMS is typically implemented. There are a number of CMMS products on the market that are adequate for handling rudimentary maintenance needs, but most maintenance departments opt to begin with CMMS products that give them a good start yet restrict their ability to move into more advanced modalities of maintenance management down the line.

Like adolescents, companies often get caught up in the moment, and are distracted from long term goals by matters that will not concern them in the next month, much less in a year or more. This means that a company will need to ensure that the CMMS product selected is not focused solely on dealing with their present situation, but rather has the capacity to grow with them as your organization’s level of maturity and development continues to advance towards QAM and utilizing the tools of RCM.

Once they commit to implement a more systematic CMMS, organizations often tend to be short-sighted on two fronts:

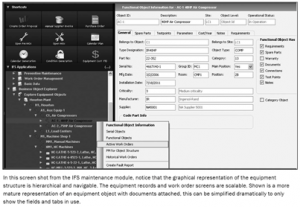

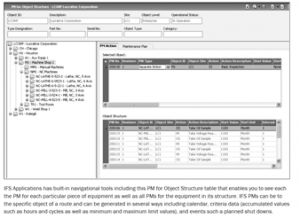

- Selecting a CMMs that will only ever be a CMMs. There are a lot of CMMS products out there that do an adequate job of scheduling the work of maintenance workers and recording that work. But many of them are not part of an overall suite of applications that provide a pathway to RCM. Some application suites, including IFS Applications, do allow for basic CMMS functionality to be implemented so that additional, enterprise-wide functionality can be added later to allow for more advanced management techniques. Many CMMS tools also keep equipment structure in a flat file rather than a hierarchical, navigable structure.

- Shortcutting implementation. For many organizations rolling out their first CMMS solution, the cost of the software license is a big investment. They are hesitant to have the vendor or any other outside party help them with implementation. But the lack of experienced and qualified help with implementation may at the very least lengthen the implementation timeline, consuming exponentially more staff time. Trying to implement CMMS on your own can also result in a suboptimal instance of the software. Either one of these outcomes can cost you many times over what it takes to have professional help with implementation.

Along with CMMS implementation, this is a good time to introduce simple, less expensive conditional components such as oil sampling and Infrared thermography. A year into a CMMS project and with simple conditional checks, there should be enough information to start developing and harvesting KPIs and Trends.

Level 4—integrated CMMs or EAM (young Adulthood)

At this stage of development, a maintenance organization begins to seriously consider how its CMMS interfaces with other systems in the company, including enterprise resource planning (ERP), equipment monitoring and project management software. If a maintenance team is cutting purchase orders and doing material requisitions in an ERP system while doing double entry by also entering them in the CMMS, it’s time to invest in an integrated package or perhaps consider bidirectional interfaces between the two systems so that they modify the same set of data.

At this stage of development, a maintenance organization begins to seriously consider how its CMMS interfaces with other systems in the company, including enterprise resource planning (ERP), equipment monitoring and project management software. If a maintenance team is cutting purchase orders and doing material requisitions in an ERP system while doing double entry by also entering them in the CMMS, it’s time to invest in an integrated package or perhaps consider bidirectional interfaces between the two systems so that they modify the same set of data.

I’ve witnessed several companies that have elected to go from Level 2 (Folders and Spreadsheets) to Level 4 (Integrated CMMS) while implementing Enterprise Resource Planning (ERP) software like IFS that offers an Enterprise Asset Management (EAM) module—and they were quite successful. I see implementing an EAM that is integrated with the ERP’s financial, supply chain and human resource pieces akin to taking college credited courses in High School and skipping your senior year to get on with college and a career. This can save a lot of time and money given a planned and disciplined approach.

If a plant has a supervisory control and data acquisition (SCADA) system, it’s time to start considering a direct interface of data (hours, strokes, alarms). Pretty much all the monitoring programs and some CMMS products are compatible through OLE Process Control (OPC) interfacing. It makes sense to have remote sampling and real-time monitoring feed directly into the CMMS in order to cut back on the man-hours necessary to collect and enter data, and to avoid misreading that leads to junk data in the CMMS.

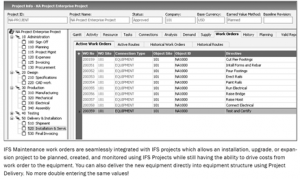

During the integrated CMMS phase, a maintenance organization can also look at integrating its maintenance software tools with project management software that can deliver equipment data directly into its CMMS. This is a huge step toward greater efficiency and the ability to manage assets over their entire lifecycle from engineering, installation, commissioning, operations, maintenance and straight through the decision to refit or replace. Machine installations, plant expansions and relocations all have asset-management relevance. The ability to manage the total cost, productivity and return on assets is only possible when early asset lifecycle stages including planning, engineering and construction are addressed in the enterprise application. This integrated approach allows for what is called asset lifecycle management (ALM)—which is a true cradle-to-grave management approach.

A condition based program can be incorporated into the maintenance program in order to garner value by doing less replacement before failure and requiring less preventative maintenance hours. We’ve discussed oil sampling and infrared thermography which can be relatively inexpensive. Some other prevalent types include; Vibration Monitoring & Analysis, Ultrasonic Noise Detection, and Non-Destructive Testing. These are all areas that require specific expertise and assessment on their potential value before implementing. A lot of people want their CMMS to do this specific data collection and analysis for them, but this is impractical. No software can do everything effectively and I’d question anyone who says they can. The CMMS just needs to have the ability to have the data attached to it. Let the specialist specialize where it makes sense and don’t fall into that “one size fits all” pit.

Once a maintenance organization has developed good basic practices outlines in this article, a definite RCM strategy should begin being developed. There are a lot of good vendors out there and this is another area where a qualified consultant should be brought in to help a dedicated maintenance team further develop their practices using RCM principles and procedures. It should be incorporated into the basic maintenance plan with defined evaluation periods and tangible benchmarks.

Level five—Quintessential Asset Management (Mature Adulthood)

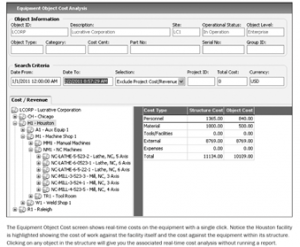

At this stage, an organization has the requisite integrated applications, equipment history and processes in place, as well as the backbone of an RCM program. You have the data on hand to help decide what equipment is truly critical instead of making that determination based on simple tribal knowledge—which often turns out to be wrong. You will have dashboards and key performance indicators that put real time data at your fingertips. You can make repair/replace decisions quickly and easily. You can make “run-to-failure” decisions with more confidence.

At this stage, an organization has the requisite integrated applications, equipment history and processes in place, as well as the backbone of an RCM program. You have the data on hand to help decide what equipment is truly critical instead of making that determination based on simple tribal knowledge—which often turns out to be wrong. You will have dashboards and key performance indicators that put real time data at your fingertips. You can make repair/replace decisions quickly and easily. You can make “run-to-failure” decisions with more confidence.

The above progression is a model of how an asset-management program develops in a real-life situation. You can throw all the buzzwords you want at it, but it comes down to common sense and a plan that unfolds over a period of time. While the right technology is important, it is your organizational culture that will really separate the wheat from the chaff and determine if you actually develop a dynamic, productive maintenance program with build in RCM principles and methodologies. A company needs a vision of where it’s going and how to get there, other than a few rows and columns on a budget spreadsheet. The people, processes, dedication and discipline are what make a maintenance program successful. Software, monitoring equipment, reliability premises and performance indicators are just tools that automate, guide and gauge your success.